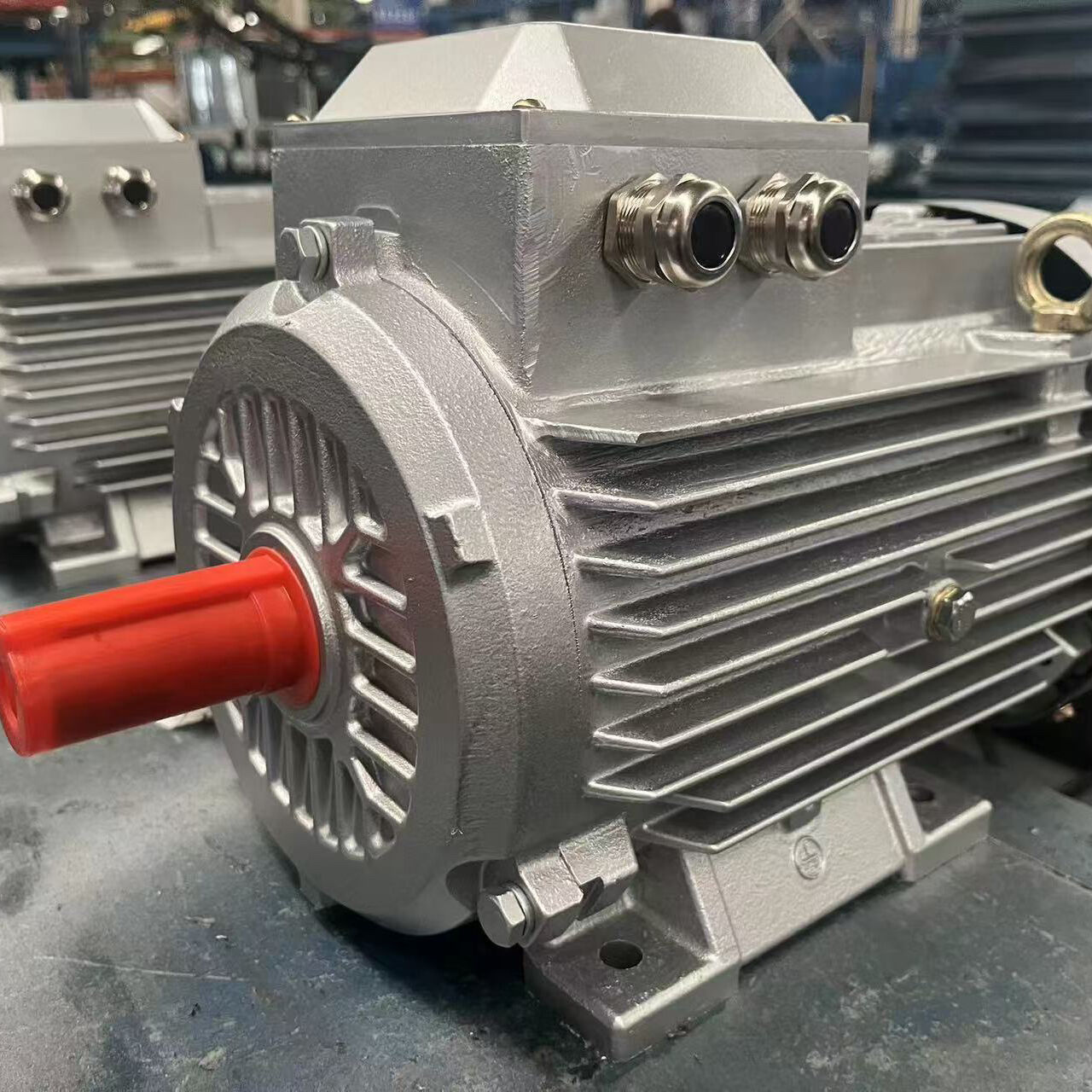

3 phase squirrel cage induction motor

The 3 phase squirrel cage induction motor represents a cornerstone of industrial power applications, characterized by its robust design and reliable performance. This motor consists of two main components: a stationary stator with three-phase windings and a rotating rotor featuring conducting bars arranged in a cage-like structure. When three-phase power is applied to the stator windings, it creates a rotating magnetic field that induces current in the rotor bars. This interaction generates electromagnetic torque, causing the rotor to spin. The motor's design eliminates the need for brushes or slip rings, significantly reducing maintenance requirements. Operating at various speeds determined by the power supply frequency and pole configuration, these motors typically achieve efficiency ratings between 85% and 95%. Common applications include industrial machinery, pumps, fans, compressors, and conveyor systems. The squirrel cage design offers superior starting torque and operates effectively under varying load conditions, making it ideal for applications requiring consistent power delivery. Modern versions incorporate advanced materials and design optimizations to enhance energy efficiency and performance reliability across different operating conditions.