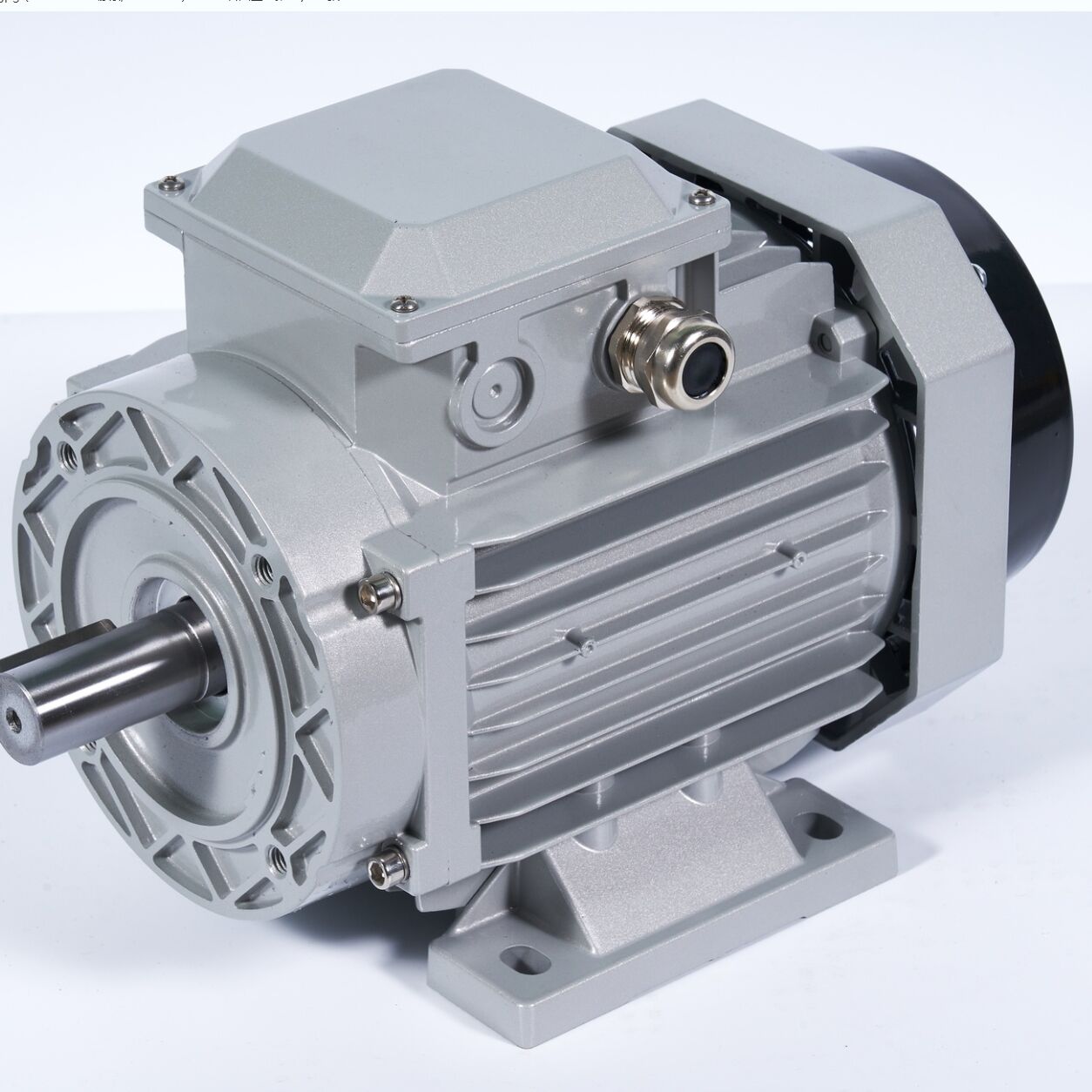

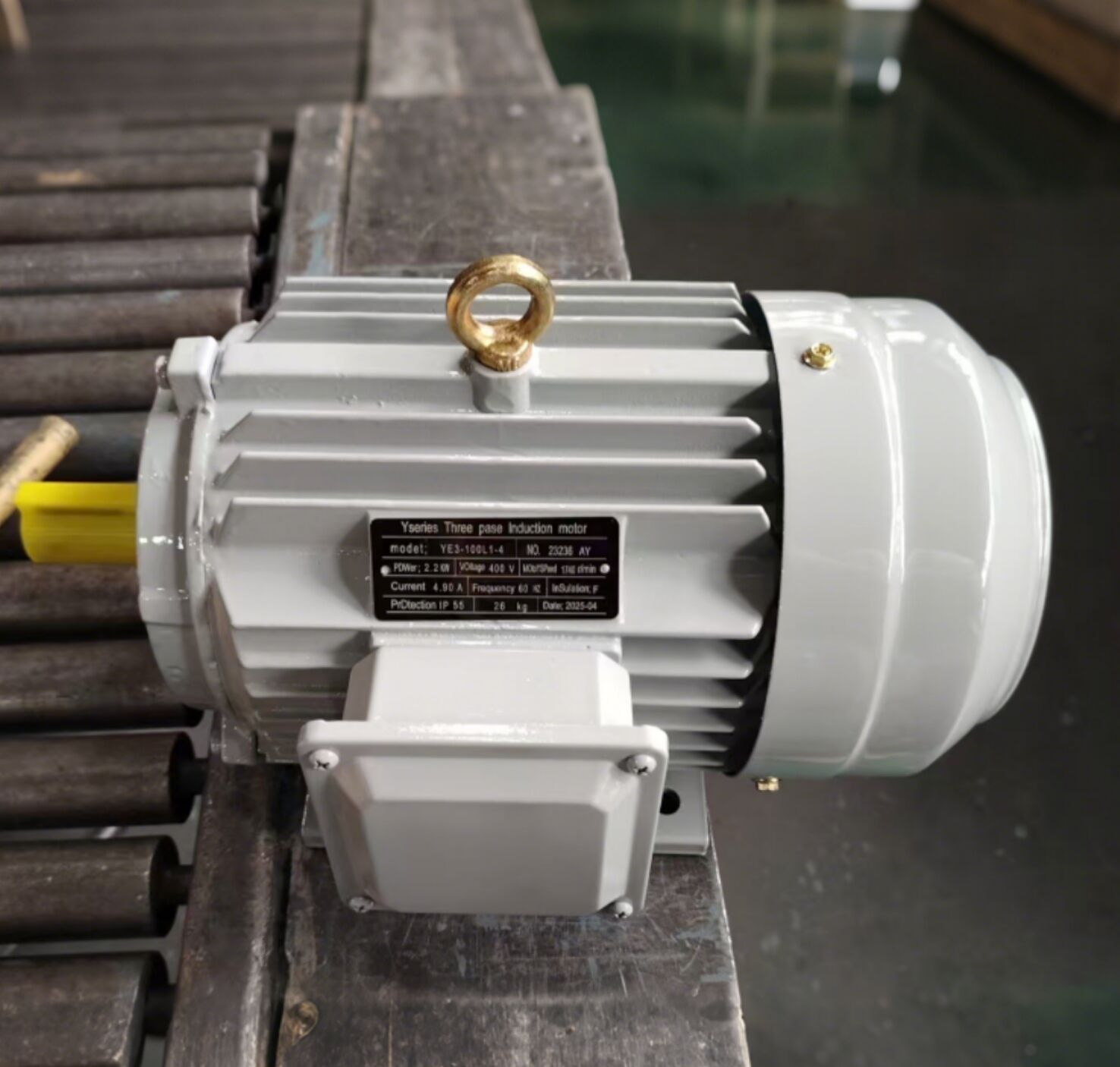

squirrel cage rotor motor

The squirrel cage rotor motor represents one of the most widely used and reliable types of induction motors in industrial applications. This motor derives its name from its distinctive rotor construction, which resembles a cage when viewed from the end. The rotor consists of aluminum or copper bars embedded in a laminated iron core and connected at both ends by shorting rings, creating a cage-like structure. When power is supplied to the stator windings, it creates a rotating magnetic field that induces current in the rotor bars. This induced current interacts with the rotating magnetic field, producing torque that causes the rotor to spin. The squirrel cage design offers exceptional mechanical strength and operational stability, making it ideal for various applications. These motors operate efficiently across different speed ranges and can handle varying load conditions without significant performance degradation. Their robust construction ensures minimal maintenance requirements and extended operational life, while their relatively simple design contributes to cost-effective manufacturing. The motor's self-starting capability and ability to operate in harsh environmental conditions make it particularly valuable in industrial settings, from powering conveyor systems to driving pumps and fans.