Power plants rely heavily on high-voltage motors to maintain consistent electrical generation and operational efficiency. These critical components form the backbone of modern energy infrastructure, driving everything from turbine generators to cooling systems and auxiliary equipment. Ensuring long-term stability of high-voltage motors requires a comprehensive understanding of their operational demands, environmental challenges, and maintenance requirements. The complexity of power plant operations means that motor failures can result in significant downtime, revenue losses, and potential safety hazards, making proactive stability measures essential for sustainable energy production.

The unique operating environment of power plants presents distinct challenges for high-voltage motors, including extreme temperatures, vibration exposure, electromagnetic interference, and continuous duty cycles. These conditions can accelerate wear patterns, degrade insulation systems, and compromise bearing integrity over time. Understanding these operational stressors is fundamental to developing effective stability strategies that extend motor lifespan while maintaining peak performance levels throughout their service life.

Understanding High-Voltage Motor Design Fundamentals

Core Construction Elements

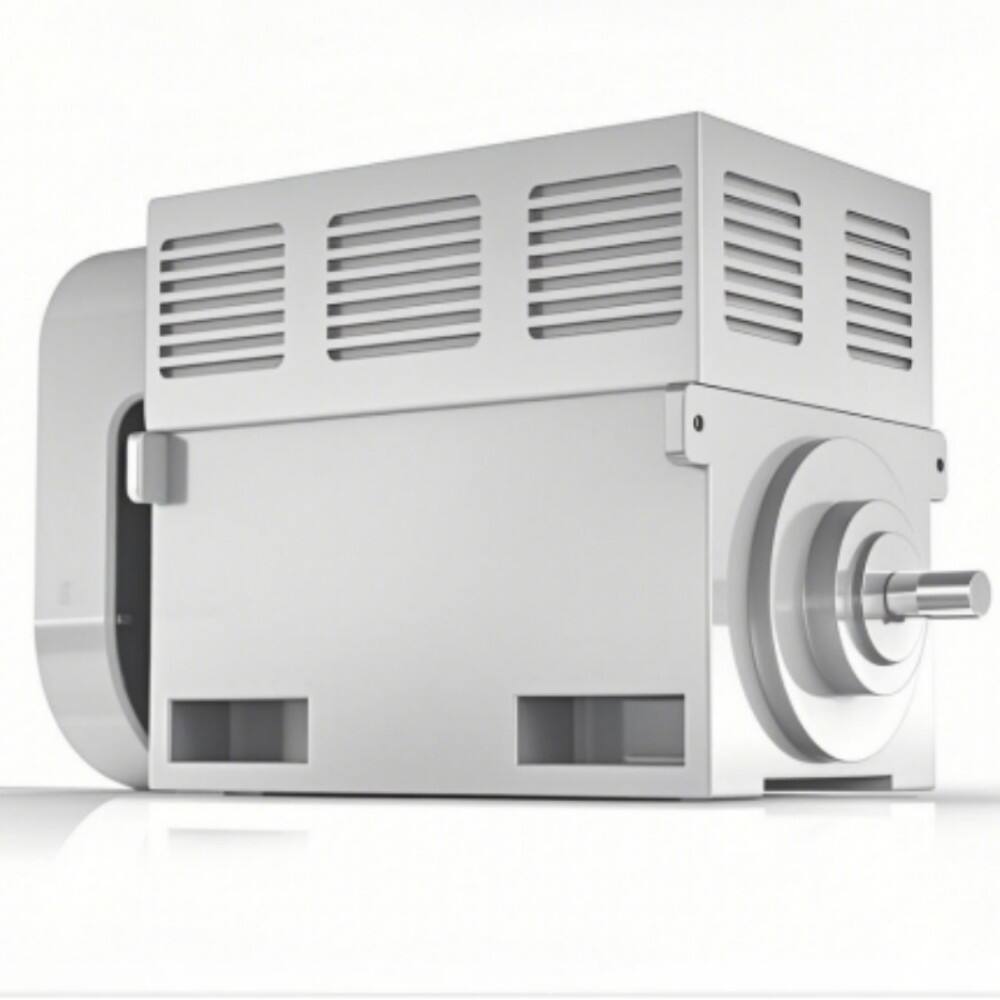

High-voltage motors incorporate specialized design features that distinguish them from standard industrial motors, particularly in their insulation systems and cooling mechanisms. The stator windings utilize advanced insulation materials capable of withstanding elevated voltage stress while maintaining dielectric strength over extended periods. These motors typically feature robust construction with reinforced frames, precision-balanced rotors, and enhanced bearing systems designed to handle the mechanical stresses inherent in power plant applications.

The rotor assembly represents a critical component requiring careful attention to magnetic balance and thermal expansion characteristics. High-voltage motors often incorporate squirrel cage or wound rotor designs, each offering specific advantages depending on the application requirements. The magnetic core materials are selected for low hysteresis losses and optimal permeability, contributing to overall efficiency and reducing heat generation during operation.

Insulation System Considerations

The insulation system serves as the primary barrier against electrical failure in high-voltage motors, requiring materials that can withstand both electrical and thermal stress over many years of service. Modern insulation systems utilize advanced epoxy resins, mica tapes, and polyester films arranged in multiple layers to provide redundant protection against voltage breakdown. The insulation class rating determines the maximum operating temperature, with Class F and Class H systems being common in power plant applications.

Proper insulation system design also considers partial discharge phenomena, which can gradually degrade insulation materials over time if not properly controlled. Advanced manufacturing techniques ensure void-free insulation application, while corona protection systems prevent surface discharge in high-voltage environments. Regular monitoring of insulation resistance and polarization index values provides early indication of insulation system degradation.

Implementing Comprehensive Maintenance Strategies

Predictive Maintenance Protocols

Predictive maintenance represents the most effective approach for ensuring long-term stability of high-voltage motors in power plant environments. Vibration analysis provides valuable insights into mechanical condition, detecting bearing wear, rotor imbalance, and coupling misalignment before these issues lead to catastrophic failure. Thermal imaging surveys identify hot spots that may indicate electrical problems, cooling system deficiencies, or mechanical friction points requiring attention.

Electrical testing protocols include insulation resistance measurements, polarization index testing, and surge comparison testing to evaluate winding condition. Motor current signature analysis can detect rotor bar defects, air gap irregularities, and load variations that may stress the motor beyond design parameters. These diagnostic techniques, when performed regularly and trended over time, enable maintenance teams to schedule repairs during planned outages rather than responding to emergency failures.

Lubrication Management Systems

Proper lubrication management is crucial for maintaining bearing integrity and preventing premature failures in high-voltage motors. Power plant environments often expose motors to contamination from dust, moisture, and chemical vapors that can degrade lubricant quality and reduce bearing life. Implementing sealed bearing systems or positive pressure lubrication chambers helps exclude contaminants while maintaining optimal lubricant film thickness.

Lubricant selection must consider operating temperature ranges, load characteristics, and compatibility with bearing materials and sealing systems. Synthetic lubricants often provide superior performance in high-temperature applications, offering extended service intervals and improved thermal stability. Regular lubricant analysis through oil sampling programs detects wear particles, contamination, and chemical degradation, enabling proactive maintenance actions before bearing damage occurs.

Environmental Protection and Cooling Systems

Temperature Management Solutions

Thermal management is critical for ensuring long-term stability of high-voltage motors, as excessive temperatures accelerate insulation aging and reduce component lifespan. Power plant installations must provide adequate ventilation and cooling to maintain motor temperatures within design limits during all operating conditions. Air-cooled systems require clean, filtered air supply with sufficient flow rates to remove heat generated by electrical losses and friction.

Water-cooled heat exchangers offer superior cooling capacity for larger high-voltage motors, particularly in applications with limited ventilation or high ambient temperatures. These systems require careful design to prevent water leakage while providing efficient heat transfer. Closed-loop cooling systems minimize contamination risks while allowing precise temperature control through automated valve systems and temperature monitoring.

Contamination Prevention Measures

Power plant environments expose high-voltage motors to various contaminants including coal dust, fly ash, chemical vapors, and moisture that can compromise motor performance and longevity. Implementing proper enclosure ratings and sealing systems prevents ingress of harmful substances while maintaining necessary cooling airflow. IP55 or higher protection ratings are typically required for power plant applications, with special consideration for corrosive environments.

Air filtration systems remove particulate contamination from cooling air, preventing accumulation on windings and cooling surfaces that can impede heat transfer and create tracking paths for electrical breakdown. Positive pressure systems maintain clean internal environments while preventing infiltration of external contaminants. Regular cleaning schedules remove accumulated deposits that could otherwise lead to overheating or insulation degradation.

Power Quality and Electrical Protection

Voltage Regulation Systems

Power quality issues significantly impact high-voltage motors stability, requiring sophisticated protection and monitoring systems to maintain safe operating conditions. Voltage variations, harmonics, and transient disturbances can stress motor insulation systems and create unbalanced magnetic forces that increase mechanical wear. Automatic voltage regulators maintain consistent supply voltage levels, while harmonic filters reduce distortion that can cause additional heating and vibration.

Surge protection devices safeguard high-voltage motors against lightning strikes and switching transients that can cause immediate insulation failure. These protective systems must coordinate with motor starting equipment and control circuits to provide comprehensive protection without interfering with normal operation. Regular testing of protection systems ensures proper functioning when abnormal conditions occur.

Motor Control Integration

Advanced motor control systems contribute to long-term stability by optimizing starting sequences, monitoring operating parameters, and implementing protective shutdown procedures. Soft starters reduce mechanical and electrical stress during motor acceleration, while variable frequency drives provide precise speed control and energy efficiency benefits. These control systems must be properly configured for high-voltage motors applications, considering insulation system ratings and cooling requirements.

Integrated monitoring systems continuously track motor performance parameters including current, voltage, temperature, and vibration levels. Automated alarm systems alert operators to developing problems before they require emergency shutdown, while data logging capabilities support trending analysis and maintenance planning. Communication protocols enable integration with plant-wide control systems for coordinated operation and maintenance scheduling.

Installation and Commissioning Best Practices

Foundation and Mounting Requirements

Proper installation forms the foundation for long-term stability of high-voltage motors in power plant applications. Motor foundations must provide adequate mass and rigidity to minimize vibration transmission while maintaining precise alignment with driven equipment. Concrete foundations require proper curing time and may incorporate vibration damping materials to reduce resonance effects that could damage motor components over time.

Mounting systems must accommodate thermal expansion while maintaining shaft alignment within acceptable tolerances. Flexible couplings accommodate minor misalignment while transmitting torque efficiently, but proper installation requires careful attention to coupling selection, alignment procedures, and periodic inspection schedules. Laser alignment tools provide the precision necessary for critical high-voltage motors installations.

Electrical Connection Standards

High-voltage electrical connections require specialized techniques and materials to ensure reliable long-term performance in power plant environments. Cable terminations must be properly prepared and installed using appropriate stress control techniques to prevent corona discharge and tracking failures. Heat-shrink or cold-applied termination systems provide reliable sealing against moisture infiltration while maintaining electrical integrity.

Grounding systems play a crucial role in motor protection, requiring low-resistance connections to facility ground networks and coordination with lightning protection systems. Proper cable routing avoids interference with other electrical systems while providing mechanical protection against damage during maintenance activities. Regular thermographic inspections identify connection problems before they lead to failures or safety hazards.

Performance Monitoring and Data Analysis

Advanced Diagnostic Technologies

Modern diagnostic technologies enable comprehensive monitoring of high-voltage motors condition without requiring equipment shutdown or disassembly. Online partial discharge monitoring systems detect insulation degradation in real-time, providing early warning of developing problems that could lead to catastrophic failure. These systems use advanced signal processing techniques to distinguish motor-related discharge activity from external interference sources.

Wireless sensor networks facilitate continuous monitoring of multiple motor parameters while reducing installation costs and maintenance requirements. Battery-powered sensors can monitor bearing temperature, vibration levels, and acoustic emissions for several years without maintenance, transmitting data to central monitoring systems for analysis and trending. Machine learning algorithms identify patterns that indicate developing problems, enabling proactive maintenance scheduling.

Data Integration and Trending

Effective data management systems integrate information from multiple monitoring sources to provide comprehensive assessment of high-voltage motors condition and performance trends. Historical data analysis reveals seasonal variations, load-related effects, and gradual degradation patterns that inform maintenance planning and replacement decisions. Predictive analytics use statistical models to forecast remaining useful life and optimize maintenance intervals.

Automated reporting systems generate regular condition summaries and exception reports that highlight motors requiring attention or showing unusual behavior patterns. Integration with maintenance management systems enables automatic work order generation and resource scheduling based on predicted maintenance needs. Performance benchmarking against similar motors helps identify optimization opportunities and validate maintenance effectiveness.

FAQ

What are the most critical factors affecting high-voltage motor longevity in power plants

The most critical factors include thermal management, contamination control, electrical power quality, and mechanical alignment. Excessive temperatures accelerate insulation aging, while contaminants like coal dust and moisture can cause tracking failures. Poor power quality creates electrical stress, and misalignment causes mechanical wear. Implementing comprehensive monitoring and maintenance programs addressing these factors significantly extends motor life while maintaining reliable operation in demanding power plant environments.

How often should high-voltage motors undergo comprehensive testing and inspection

Comprehensive testing should occur annually for critical high-voltage motors, with quarterly inspections for visual assessment and basic measurements. Continuous online monitoring provides real-time condition data, while detailed electrical testing including insulation resistance, polarization index, and surge testing should be performed during scheduled maintenance outages. The frequency may be adjusted based on motor criticality, operating history, and trending data from continuous monitoring systems.

What are the warning signs that indicate potential high-voltage motor problems

Key warning signs include increasing bearing temperatures, unusual vibration patterns, declining insulation resistance values, abnormal current consumption, and unusual acoustic emissions. Visual indicators such as corona discharge, moisture accumulation, or contamination buildup also warrant immediate attention. Modern monitoring systems can detect these conditions early through automated analysis, enabling corrective action before problems escalate to motor failure or safety hazards.

How do environmental conditions in power plants affect high-voltage motor selection and maintenance

Power plant environments require motors with enhanced protection ratings, corrosion-resistant materials, and robust cooling systems. High ambient temperatures, chemical vapors, and particulate contamination influence insulation system selection, enclosure design, and maintenance intervals. Motors must be sized for continuous duty cycles with appropriate service factors, while maintenance programs must account for accelerated aging effects from harsh environmental conditions through more frequent inspections and component replacements.

Table of Contents

- Understanding High-Voltage Motor Design Fundamentals

- Implementing Comprehensive Maintenance Strategies

- Environmental Protection and Cooling Systems

- Power Quality and Electrical Protection

- Installation and Commissioning Best Practices

- Performance Monitoring and Data Analysis

-

FAQ

- What are the most critical factors affecting high-voltage motor longevity in power plants

- How often should high-voltage motors undergo comprehensive testing and inspection

- What are the warning signs that indicate potential high-voltage motor problems

- How do environmental conditions in power plants affect high-voltage motor selection and maintenance