Industrial operations across manufacturing, mining, construction, and processing industries rely heavily on robust mechanical systems to handle demanding workloads. At the heart of these systems lie gear reducers, sophisticated mechanical devices that transform high-speed, low-torque input from motors into lower-speed, higher-torque output suitable for heavy-duty applications. Understanding how to select the appropriate gear reducers for your specific industrial needs can significantly impact operational efficiency, equipment longevity, and overall productivity. The selection process involves careful consideration of multiple factors including load requirements, environmental conditions, space constraints, and long-term maintenance considerations.

Understanding the Four Major Series of Gear Reducers

Helical Gear Reducers for Precision Applications

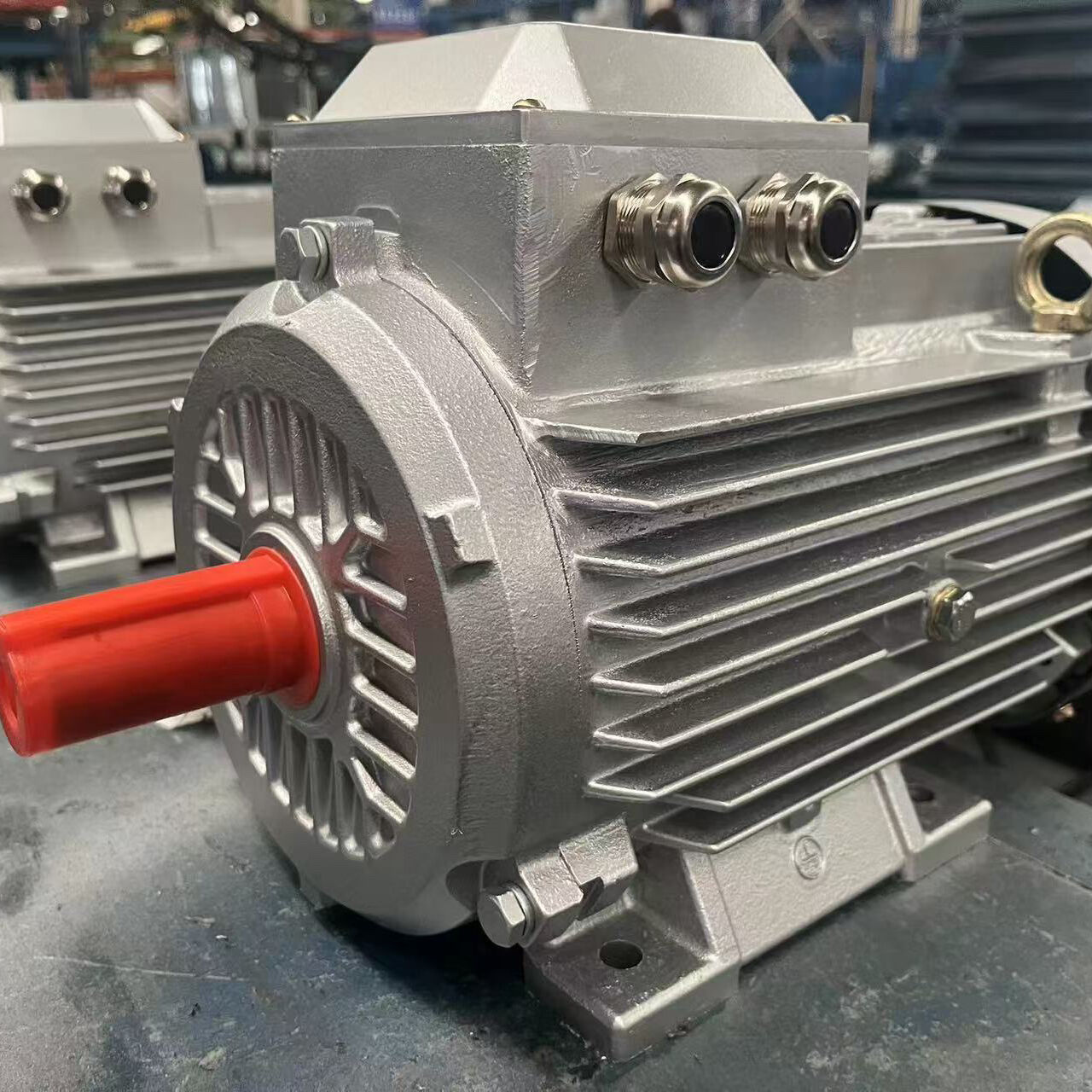

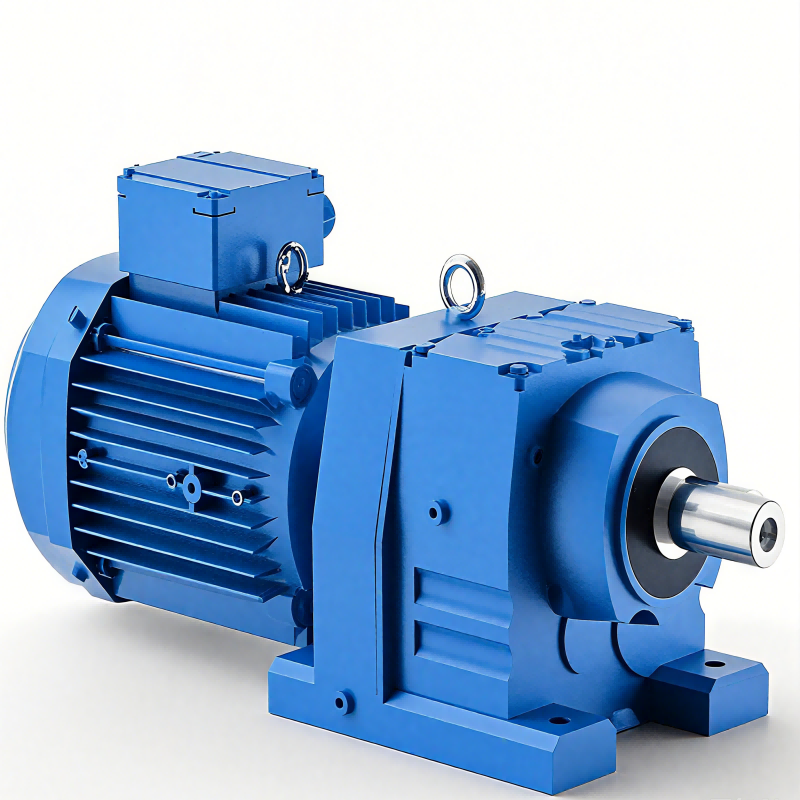

Helical gear reducers represent one of the most widely adopted solutions in heavy-duty industrial applications due to their exceptional efficiency and smooth operation characteristics. These gear reducers feature angled teeth that engage gradually, resulting in reduced noise levels and enhanced load distribution compared to straight-cut alternatives. The helical design enables higher torque transmission capabilities while maintaining compact dimensions, making them ideal for applications where space optimization is crucial. Manufacturing facilities processing continuous materials, conveyor systems handling bulk products, and automated assembly lines frequently rely on helical gear reducers for their reliability and performance consistency.

The engineering advantages of helical gear reducers extend beyond basic torque multiplication to include superior heat dissipation and extended operational life cycles. Advanced manufacturing techniques now incorporate hardened tooth surfaces and precision grinding processes, ensuring these gear reducers maintain their performance characteristics even under extreme operational conditions. When selecting helical gear reducers for heavy-duty applications, engineers must consider factors such as backlash requirements, mounting configurations, and thermal management capabilities to ensure optimal system integration and long-term reliability.

Worm Gear Reducers for High Reduction Ratios

Worm gear reducers excel in applications requiring substantial speed reduction ratios while maintaining self-locking capabilities that prevent reverse rotation. These specialized gear reducers utilize a worm screw mechanism that meshes with a worm wheel, creating reduction ratios that can exceed 100:1 in single-stage configurations. Heavy-duty lifting equipment, positioning systems, and material handling machinery benefit significantly from the inherent safety features and compact design characteristics of worm gear reducers. The self-locking property eliminates the need for additional braking systems in many vertical load applications, simplifying system design and reducing overall component costs.

Modern worm gear reducers incorporate advanced materials and lubrication systems to address traditional efficiency limitations associated with sliding contact between gear elements. Bronze worm wheels paired with hardened steel worm screws provide optimal wear characteristics and extended service intervals. When evaluating worm gear reducers for heavy-duty installations, consideration must be given to thermal management requirements, as the sliding action generates more heat compared to other gear reducer types. Proper cooling strategies and high-quality synthetic lubricants enable these systems to achieve reliable performance in demanding industrial environments.

Planetary Gear Systems for Compact Power Transmission

High Power Density Applications

Planetary gear reducers offer exceptional power-to-weight ratios, making them indispensable for applications where space constraints and weight limitations are critical design factors. These sophisticated gear reducers utilize multiple planet gears arranged around a central sun gear, with power transmission occurring through a ring gear assembly. The distributed load sharing among multiple gear meshes enables planetary systems to handle significantly higher torques than comparable single-mesh configurations. Mobile equipment, robotics applications, and aerospace systems frequently specify planetary gear reducers due to their compact form factors and exceptional durability under varying load conditions.

The modular nature of planetary gear reducers allows for flexible ratio combinations and multi-stage configurations to achieve precise speed reduction requirements. Advanced planetary designs incorporate precision-machined components and specialized bearing systems to minimize backlash and maximize positioning accuracy. Heavy-duty applications benefit from the inherent redundancy of planetary systems, where individual planet gear failure does not result in immediate system shutdown. Selection criteria for planetary gear reducers must account for dynamic loading conditions, environmental exposure, and maintenance accessibility to ensure optimal long-term performance in demanding industrial settings.

Engineering teams evaluating planetary gear reducers for heavy-duty applications should prioritize systems with hardened gear surfaces and robust carrier assemblies capable of withstanding shock loads and operational variations. The integration of advanced sealing systems and premium lubricants extends service intervals and reduces maintenance requirements, critical factors in continuous operation environments where unplanned downtime carries significant economic penalties.

Precision Control and Positioning Systems

Precision planetary gear reducers serve critical roles in applications requiring accurate positioning and smooth motion control characteristics. Manufacturing equipment, CNC machinery, and automated material handling systems depend on the minimal backlash and high torsional stiffness provided by quality planetary designs. The symmetrical load distribution inherent in planetary configurations results in reduced bearing loads and extended component life compared to other gear reducer architectures. Advanced planetary systems incorporate specialized anti-backlash mechanisms and precision-ground gear teeth to achieve positioning accuracies measured in arc-minutes.

The selection process for precision planetary gear reducers involves careful evaluation of dynamic performance characteristics including acceleration capabilities, settling time, and thermal stability under varying load conditions. High-performance applications often specify gear reducers with integrated feedback systems and temperature monitoring capabilities to ensure consistent performance throughout operational cycles. Quality planetary systems designed for heavy-duty precision applications incorporate advanced materials and surface treatments to maintain accuracy specifications over extended service periods while withstanding the mechanical stresses associated with frequent direction changes and varying load conditions.

Bevel Gear Configurations for Angular Power Transmission

Right-Angle Drive Solutions

Bevel gear reducers provide essential angular power transmission capabilities for applications where input and output shafts must be positioned at specific angles to accommodate equipment layout constraints. These specialized gear reducers typically operate at 90-degree angles, although custom configurations can accommodate various angular requirements based on application specifications. Heavy-duty conveyor systems, mining equipment, and agricultural machinery frequently incorporate bevel gear reducers to redirect power flow while maintaining efficient torque transmission. The robust construction of industrial bevel systems enables reliable operation under high shock loads and varying environmental conditions common in heavy-duty applications.

Modern bevel gear reducers utilize advanced manufacturing techniques including computer-controlled grinding and heat treatment processes to achieve superior surface finishes and dimensional accuracy. Spiral bevel designs offer enhanced load distribution and smoother operation compared to straight bevel configurations, making them preferable for continuous-duty applications. The selection of appropriate bevel gear reducers requires consideration of shaft positioning requirements, mounting flexibility, and service accessibility to ensure successful integration into existing equipment configurations while maintaining optimal performance characteristics.

Heavy-Duty Mining and Construction Applications

Bevel gear reducers designed for mining and construction environments must withstand extreme operating conditions including high shock loads, abrasive contaminants, and temperature variations. These rugged systems incorporate reinforced housings, premium sealing systems, and specialized lubrication arrangements to ensure reliable operation in challenging industrial environments. Quarry equipment, earthmoving machinery, and materials processing systems rely on the durability and performance consistency of properly specified bevel gear reducers to maintain productivity levels while minimizing maintenance requirements and operational disruptions.

The engineering requirements for heavy-duty bevel gear reducers extend beyond basic mechanical specifications to include contamination resistance, thermal management, and service life optimization. Advanced bevel systems incorporate features such as labyrinth seals, breather systems, and condition monitoring capabilities to maximize operational reliability in demanding environments. Selection criteria must account for peak load conditions, duty cycle variations, and environmental exposure levels to ensure the chosen gear reducers provide reliable service throughout their intended operational life while meeting safety and performance requirements.

Performance Optimization and Selection Criteria

Load Analysis and Torque Requirements

Accurate load analysis forms the foundation of proper gear reducer selection for heavy-duty applications, requiring comprehensive evaluation of operational torque requirements, peak loading conditions, and duty cycle characteristics. Engineers must consider both steady-state torque demands and dynamic loading events such as startup transients, emergency stops, and shock loads that can significantly exceed normal operating conditions. Modern gear reducers incorporate service factors and safety margins to accommodate these variable loading conditions while maintaining reliable performance throughout their operational life. Advanced load analysis techniques utilize computer modeling and field data collection to establish accurate loading profiles that inform optimal gear reducer specifications.

The relationship between input speed, output torque, and reduction ratio directly impacts gear reducer selection and sizing requirements. Higher reduction ratios generally provide greater torque multiplication but may introduce efficiency losses and increased complexity that must be balanced against application requirements. Heavy-duty applications often benefit from multi-stage gear reducers that optimize the balance between torque capacity, efficiency, and physical dimensions. Professional selection of gear reducers requires careful consideration of thermal loading, lubrication requirements, and mechanical stress distribution to ensure long-term reliability under specified operating conditions.

Environmental Considerations and Protection Standards

Environmental factors play crucial roles in gear reducer selection and specification for heavy-duty applications, with considerations including temperature extremes, moisture exposure, chemical compatibility, and contamination resistance. Industrial environments often expose mechanical equipment to conditions that exceed standard operating parameters, requiring specialized gear reducers with enhanced protection features and materials compatibility. Corrosion-resistant coatings, upgraded sealing systems, and temperature-compensated lubricants enable reliable operation in challenging environmental conditions while maintaining performance specifications throughout extended service periods.

Protection standard ratings such as IP classifications define the level of environmental protection provided by gear reducer enclosures against dust, moisture, and other contaminants common in industrial settings. Heavy-duty applications frequently require IP65 or higher protection levels to ensure reliable operation in washdown environments, outdoor installations, and facilities with airborne contaminants. The selection process must evaluate long-term environmental exposure effects on gear reducer components and specify appropriate protection measures to maintain operational reliability while minimizing maintenance requirements and extending service intervals between major overhauls.

Installation and Maintenance Best Practices

Proper Mounting and Alignment Procedures

Successful installation of gear reducers in heavy-duty applications requires adherence to precise mounting and alignment procedures that ensure optimal load distribution and minimize premature component wear. Foundation preparation, shaft alignment, and coupling selection directly impact operational smoothness and service life of gear reducer systems. Professional installation practices include the use of precision alignment tools, proper torque specifications, and systematic verification procedures to confirm correct installation before commissioning. Misalignment conditions can generate excessive loading, vibration, and heat generation that significantly reduce gear reducer performance and reliability.

Modern installation techniques incorporate laser alignment systems and computerized balancing equipment to achieve alignment tolerances that maximize gear reducer performance and minimize operational stresses. Base grouting, vibration isolation, and thermal expansion accommodation must be considered during installation planning to ensure long-term dimensional stability and alignment maintenance. Quality installation procedures also address lubrication system preparation, initial fill procedures, and break-in protocols that establish optimal operating conditions from the initial startup through normal operational cycles.

Preventive Maintenance and Monitoring Systems

Comprehensive preventive maintenance programs maximize the operational life and reliability of gear reducers in heavy-duty applications through systematic monitoring, lubrication management, and component inspection protocols. Modern maintenance strategies incorporate condition monitoring technologies including vibration analysis, thermal imaging, and oil analysis to detect developing problems before they result in equipment failure or unplanned downtime. Predictive maintenance techniques enable maintenance teams to schedule repairs during planned outages while optimizing component replacement intervals based on actual condition rather than arbitrary time-based schedules.

Lubrication management represents a critical aspect of gear reducer maintenance, with proper oil selection, change intervals, and contamination control directly impacting component life and operational efficiency. Advanced synthetic lubricants provide enhanced performance characteristics including improved temperature stability, extended change intervals, and superior component protection under extreme operating conditions. Maintenance programs for heavy-duty gear reducers should include regular inspections of sealing systems, mounting hardware, and coupling components to identify potential problems before they compromise system reliability or safety.

FAQ

What are the key differences between helical and worm gear reducers for heavy-duty applications

Helical gear reducers offer higher efficiency ratings, typically 95-98%, and can handle higher input speeds compared to worm gear reducers, which generally achieve 70-90% efficiency but provide superior self-locking capabilities and higher reduction ratios in single-stage configurations. Helical designs excel in continuous-duty applications requiring high efficiency and smooth operation, while worm gear reducers are preferred for positioning applications and vertical loads where self-locking prevents back-driving. The choice between these gear reducer types depends on specific application requirements including efficiency priorities, reduction ratio needs, and safety considerations related to load holding capabilities.

How do I determine the appropriate service factor for my gear reducer application

Service factor selection depends on operational characteristics including load uniformity, starting frequency, shock loading conditions, and duty cycle variations. Applications with smooth loading and infrequent starts typically require service factors of 1.0-1.25, while equipment subject to shock loads or frequent reversals may need service factors of 1.5-2.0 or higher. Heavy-duty applications should consider peak torque events, environmental conditions, and reliability requirements when determining appropriate service factors. Consulting with gear reducer manufacturers and reviewing application-specific guidelines ensures proper sizing and long-term reliability under actual operating conditions.

What maintenance intervals are recommended for heavy-duty gear reducers

Maintenance intervals for heavy-duty gear reducers vary based on operating conditions, environmental factors, and manufacturer specifications, but typically include initial oil changes after 500-1000 operating hours followed by regular intervals of 2500-5000 hours for mineral oils or 5000-8000 hours for synthetic lubricants. Harsh environments or high-load applications may require more frequent maintenance, while condition monitoring systems can extend intervals by providing real-time component health information. Regular inspections should include vibration monitoring, temperature checks, and oil analysis to optimize maintenance timing based on actual equipment condition rather than fixed schedules.

Can gear reducers be customized for specific heavy-duty applications

Yes, reputable gear reducer manufacturers offer extensive customization options including special mounting configurations, non-standard ratios, enhanced sealing systems, and materials upgrades to meet specific heavy-duty application requirements. Custom modifications may include explosion-proof enclosures, special coatings for corrosive environments, integrated cooling systems, and application-specific input/output arrangements. The customization process typically involves detailed application analysis, engineering review, and performance validation to ensure the modified gear reducers meet all operational requirements while maintaining reliability and safety standards. Lead times and costs for custom gear reducers vary based on the extent of modifications required and manufacturer capabilities.

Table of Contents

- Understanding the Four Major Series of Gear Reducers

- Planetary Gear Systems for Compact Power Transmission

- Bevel Gear Configurations for Angular Power Transmission

- Performance Optimization and Selection Criteria

- Installation and Maintenance Best Practices

-

FAQ

- What are the key differences between helical and worm gear reducers for heavy-duty applications

- How do I determine the appropriate service factor for my gear reducer application

- What maintenance intervals are recommended for heavy-duty gear reducers

- Can gear reducers be customized for specific heavy-duty applications