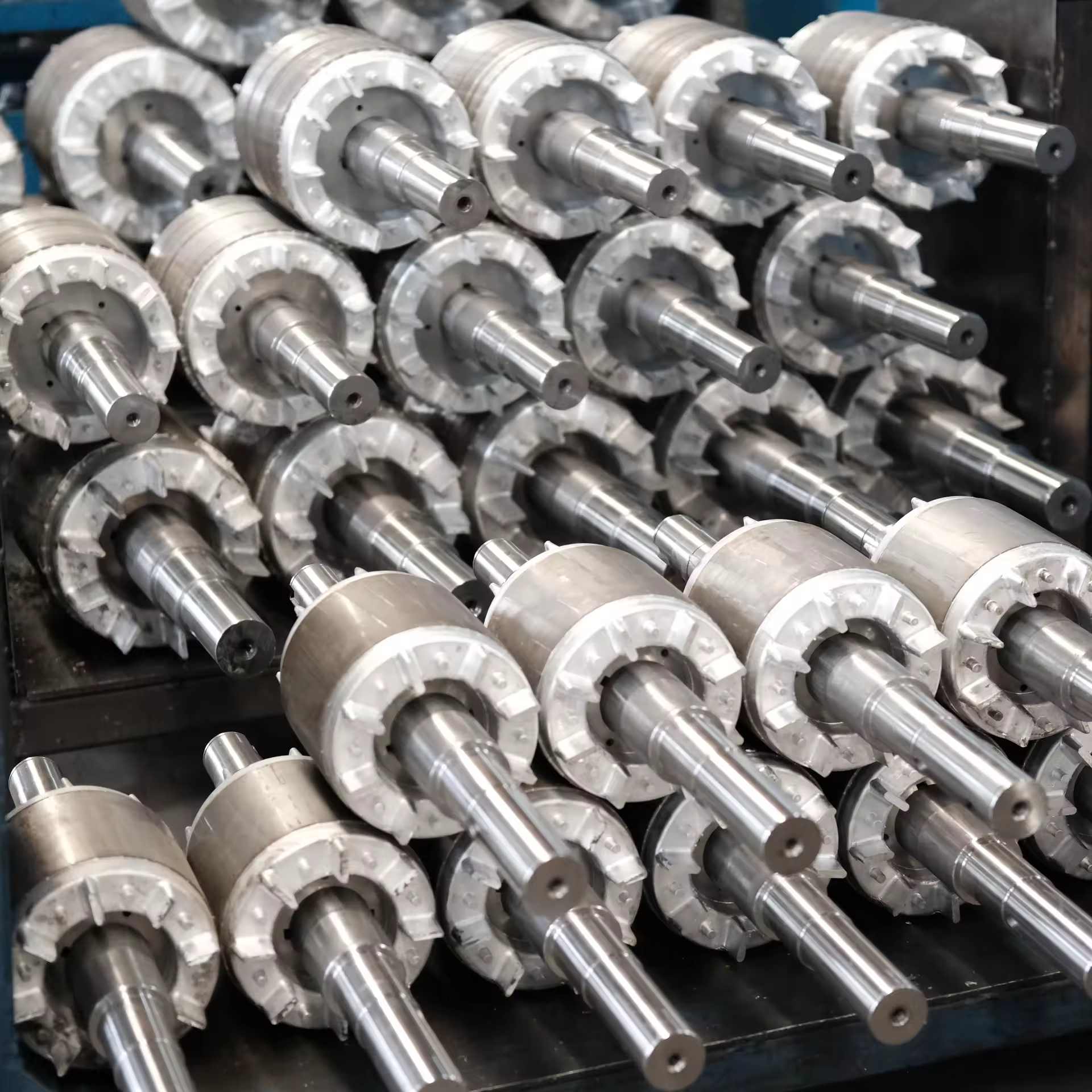

Original Equipment Manufacturers (OEMs) across industries are increasingly turning to customized stator and rotor solutions to meet their specific application requirements and competitive demands. These specialized electromagnetic components serve as the heart of electric motors, generators, and other rotating electrical machines, making their precise design and manufacturing critical for optimal performance. The shift toward customization represents a strategic response to market pressures for higher efficiency, reduced costs, and enhanced product differentiation in an increasingly competitive landscape.

Market Drivers Behind Custom Electromagnetic Components

Performance Optimization Requirements

Modern industrial applications demand precise performance characteristics that standard off-the-shelf components simply cannot deliver. OEMs working with electric vehicles, renewable energy systems, and advanced manufacturing equipment require motors with specific torque curves, speed ranges, and efficiency profiles. Customized stator and rotor solutions enable manufacturers to achieve these exact specifications by tailoring lamination thickness, winding configurations, and magnetic materials to match application requirements. This level of customization results in motors that operate at peak efficiency within their intended operating envelope, delivering superior performance compared to generic alternatives.

The ability to optimize electromagnetic design parameters allows OEMs to push the boundaries of what their products can achieve. For instance, electric vehicle manufacturers can specify rotors with particular magnetic flux densities to maximize power output while minimizing weight, directly impacting vehicle range and acceleration. Similarly, wind turbine generators benefit from custom stator designs that optimize power generation across varying wind speeds, improving overall energy capture and grid stability.

Competitive Differentiation Strategies

In saturated markets, product differentiation becomes crucial for maintaining competitive advantage and market share. Custom electromagnetic solutions provide OEMs with unique selling propositions that cannot be easily replicated by competitors using standard components. This differentiation extends beyond mere performance metrics to include form factors, integration capabilities, and specialized features that align with specific customer needs. The investment in customized stator and rotor solutions often pays dividends through premium pricing opportunities and stronger customer loyalty.

Furthermore, custom solutions enable OEMs to create products with distinctive characteristics that become part of their brand identity. These unique electromagnetic signatures can translate into recognizable performance traits that customers associate with quality and innovation, building long-term brand equity in competitive markets.

Technical Advantages of Custom Electromagnetic Design

Efficiency Enhancement Opportunities

Energy efficiency has become a paramount concern across all industries, driven by both regulatory requirements and operational cost considerations. Customized stator and rotor solutions offer unprecedented opportunities to maximize efficiency by optimizing every aspect of the electromagnetic design. This includes selecting appropriate steel grades for laminations, designing optimal slot configurations for windings, and choosing magnetic materials that minimize losses while maximizing flux density. The result is motors that can achieve efficiency ratings significantly higher than standard alternatives.

Advanced simulation tools and electromagnetic modeling software enable designers to evaluate thousands of design variations before settling on optimal configurations. This computational approach to customization ensures that the final product delivers maximum efficiency while meeting all performance requirements, often exceeding industry standards and regulatory mandates.

Thermal Management Integration

Effective heat dissipation is crucial for maintaining performance and extending component life in electric motors. Custom electromagnetic designs allow for integrated thermal management solutions that cannot be achieved with standard components. This includes optimized cooling channel designs within stator cores, specialized lamination patterns that enhance heat transfer, and rotor configurations that minimize heat generation through reduced losses.

The ability to design thermal management into the electromagnetic components from the ground up results in motors that can operate at higher power densities without compromising reliability. This integration is particularly valuable in applications where space constraints make external cooling systems impractical or where silent operation is required.

Manufacturing and Supply Chain Benefits

Production Flexibility and Scalability

Working with suppliers who specialize in customized stator and rotor solutions provides OEMs with significant manufacturing flexibility that extends beyond just product design. Custom manufacturing partnerships often include scalable production capabilities that can adapt to changing demand patterns without the constraints typically associated with standard component procurement. This flexibility allows OEMs to respond quickly to market opportunities and adjust production volumes based on real-time demand signals.

Additionally, custom manufacturing relationships frequently involve collaborative engineering support that continues throughout the product lifecycle. This ongoing partnership ensures that design improvements, cost reductions, and quality enhancements can be implemented continuously, providing long-term competitive advantages that compound over time.

Quality Control and Traceability

Custom electromagnetic component manufacturing typically involves more rigorous quality control processes compared to mass-produced alternatives. This enhanced quality focus includes material traceability, detailed process documentation, and comprehensive testing protocols that ensure each component meets exact specifications. For OEMs in regulated industries such as aerospace, medical devices, or automotive applications, this level of quality control and documentation is often mandatory rather than optional.

The traceability capabilities inherent in custom manufacturing processes also support better field service and warranty management. When issues arise, OEMs can quickly identify affected products and implement targeted solutions, minimizing downtime and maintaining customer satisfaction while reducing warranty costs.

Economic Considerations and ROI Analysis

Total Cost of Ownership Benefits

While customized stator and rotor solutions may carry higher initial costs compared to standard components, the total cost of ownership analysis often reveals significant long-term savings. These savings come from multiple sources including reduced energy consumption due to higher efficiency, lower maintenance requirements due to optimized designs, and extended service life due to better thermal management and reduced stress concentrations.

OEMs that conduct comprehensive lifecycle cost analyses frequently discover that the premium paid for custom electromagnetic components is recovered within the first few years of operation through reduced operational costs. This economic advantage becomes even more pronounced in applications where energy costs are significant or where downtime carries high penalties.

Market Premium Capture

Products incorporating customized stator and rotor solutions often command premium pricing in the marketplace due to their superior performance characteristics and unique capabilities. This price premium can significantly offset the additional investment in custom components while improving overall profit margins. The key is effectively communicating the value proposition to customers and quantifying the benefits in terms they understand and value.

Market research consistently shows that customers are willing to pay premiums for products that deliver measurable improvements in efficiency, reliability, or performance. Custom electromagnetic solutions enable OEMs to deliver these improvements while maintaining competitive positioning in their respective markets.

Future Trends and Technology Evolution

Advanced Materials Integration

The electromagnetic component industry is experiencing rapid innovation in materials science, with new magnetic materials, advanced steel alloys, and innovative insulation systems becoming available regularly. Customized stator and rotor solutions provide the ideal platform for integrating these advanced materials as they become commercially viable, allowing OEMs to stay at the forefront of technology development.

Emerging materials such as amorphous metals, nanocrystalline alloys, and advanced permanent magnet compositions offer the potential for step-change improvements in motor performance. However, these materials often require specialized design approaches and manufacturing processes that are only feasible within custom development programs.

Digital Twin and Simulation Integration

The integration of digital twin technology with custom electromagnetic design is revolutionizing how OEMs approach product development and optimization. Digital twins enable real-time performance monitoring and predictive maintenance capabilities that extend far beyond what is possible with standard components. This technology integration allows for continuous optimization of electromagnetic designs based on actual operating data and performance feedback.

Furthermore, advanced simulation capabilities are making it possible to optimize electromagnetic designs for multiple operating conditions simultaneously, ensuring that customized stator and rotor solutions deliver optimal performance across their entire operating envelope. This multi-objective optimization approach results in components that are truly tailored to specific applications rather than merely modified from standard designs.

FAQ

What are the typical lead times for customized stator and rotor solutions?

Lead times for customized stator and rotor solutions typically range from 8 to 16 weeks, depending on the complexity of the design and the extent of customization required. Initial prototyping phases may take 4 to 6 weeks, followed by design validation and tooling preparation. Production lead times can often be reduced for repeat orders once tooling and processes are established. OEMs should plan for longer development cycles during the initial design phase but can expect more predictable delivery schedules for ongoing production requirements.

How do custom electromagnetic solutions impact product certification and compliance?

Custom electromagnetic solutions can actually facilitate compliance with industry standards and regulations by allowing designs to be optimized specifically for certification requirements. Experienced custom manufacturers typically provide comprehensive documentation and test data that support certification processes. However, OEMs should engage with their certification bodies early in the design process to ensure that custom solutions meet all applicable standards. The additional documentation and traceability inherent in custom manufacturing often streamlines rather than complicates certification processes.

What minimum order quantities are typically required for custom electromagnetic components?

Minimum order quantities for customized stator and rotor solutions vary significantly based on the level of customization and manufacturing processes involved. Simple modifications to existing designs may have minimum orders as low as 100 pieces, while completely custom designs typically require minimum orders of 500 to 1,000 pieces to justify tooling costs. Many manufacturers offer prototype quantities for design validation before committing to full production runs, allowing OEMs to verify performance before placing larger orders.

Can existing motor designs be retrofitted with custom stator and rotor components?

Retrofit applications for custom electromagnetic components are possible but require careful consideration of mechanical interfaces, thermal characteristics, and electromagnetic compatibility. The feasibility depends largely on the existing motor housing design and available space for modifications. In many cases, it may be more cost-effective to design a completely new motor assembly rather than attempting to retrofit existing designs. However, for high-value applications or where existing infrastructure must be preserved, retrofit solutions can provide significant performance improvements over standard replacement components.

Table of Contents

- Market Drivers Behind Custom Electromagnetic Components

- Technical Advantages of Custom Electromagnetic Design

- Manufacturing and Supply Chain Benefits

- Economic Considerations and ROI Analysis

- Future Trends and Technology Evolution

-

FAQ

- What are the typical lead times for customized stator and rotor solutions?

- How do custom electromagnetic solutions impact product certification and compliance?

- What minimum order quantities are typically required for custom electromagnetic components?

- Can existing motor designs be retrofitted with custom stator and rotor components?