Compared with traditional brushed DC motors (BDC), BLDC motors eliminate mechanical commutators and brushes, offering advantages such as higher efficiency, longer service life, lower noise, and less maintenance. As a result, they are widely used in electric vehicles, drones,

home appliances, industrial automation, medical equipment, and other fields.

5. Brushed DC Motor (BDC)

A BDC is a DC motor that achieves commutation through a mechanical commutator (brushes and commutator). It relies on the contact between carbon brushes and the commutator to change the current direction continuously, driving the rotor to rotate.

Although BDCs are gradually being replaced by BLDCs in some applications, they are still widely used in many industrial and consumer devices due to their low cost, simple control, and high starting torque.

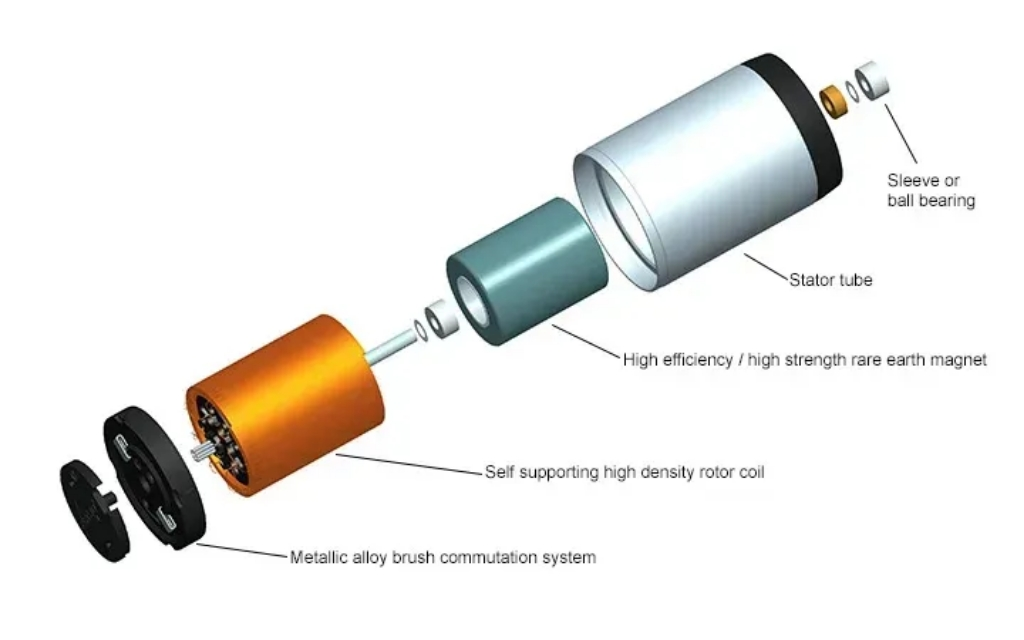

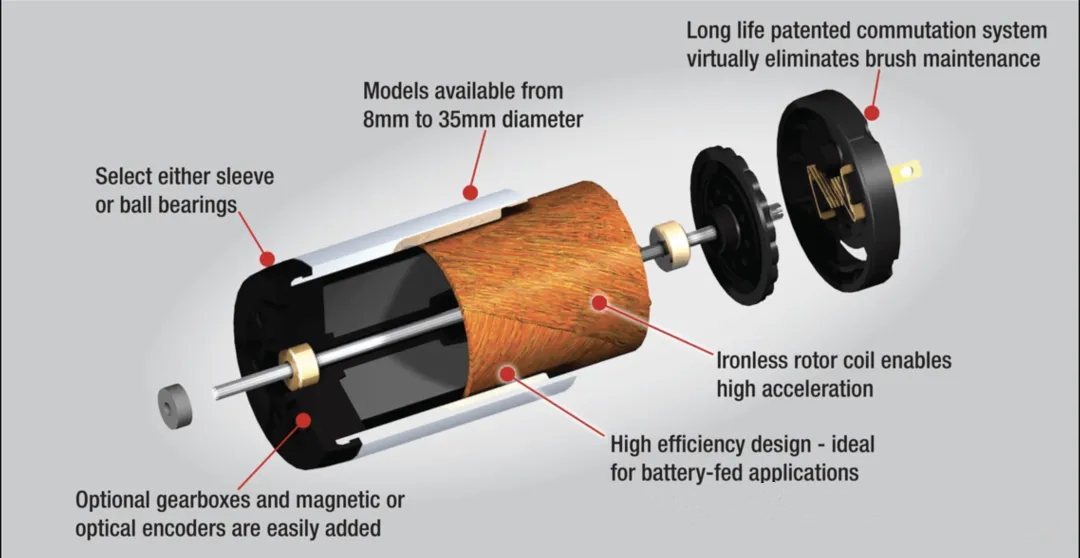

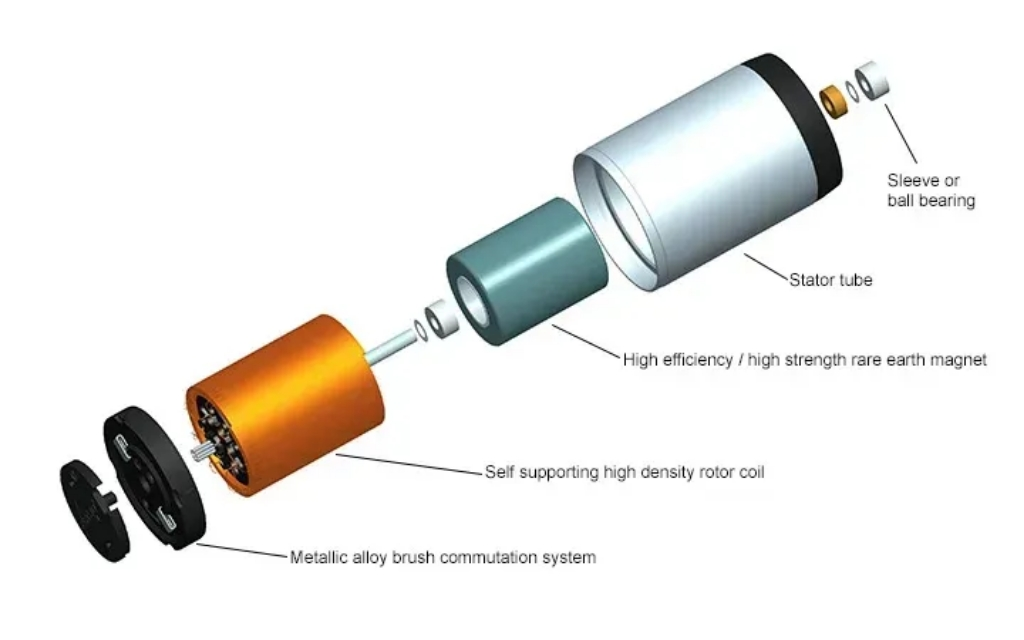

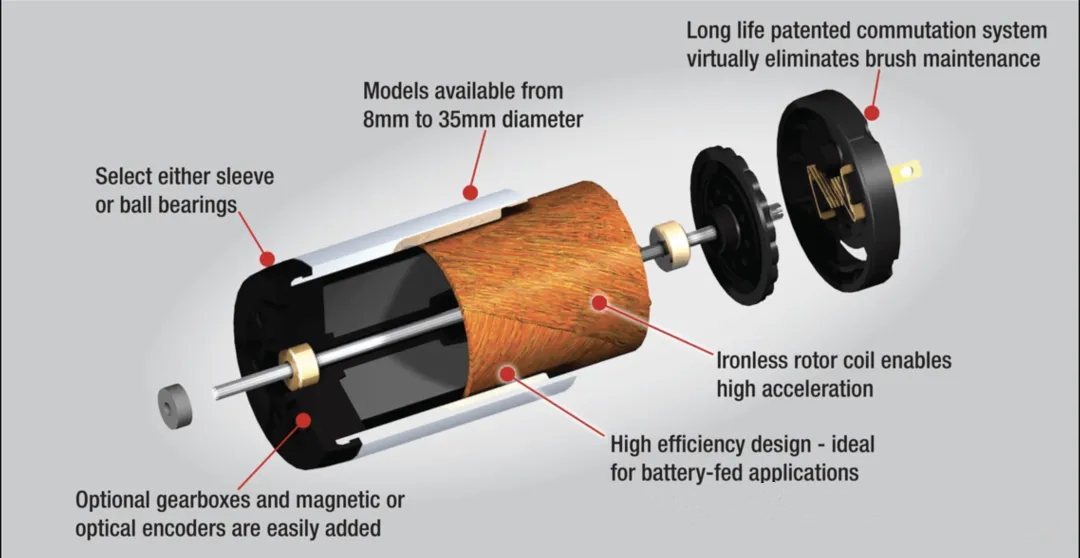

The brushed DC motor technology in the diagram originates from a design based on an ironless rotor (self-supporting coils), combined with a noble metal or carbon-copper commutation system and rare-earth or alnico magnets.

All DC motors consist of three main sub-components:

2. Brush Holder End Cover

3. Rotor

6. Liquid-Cooled Motor

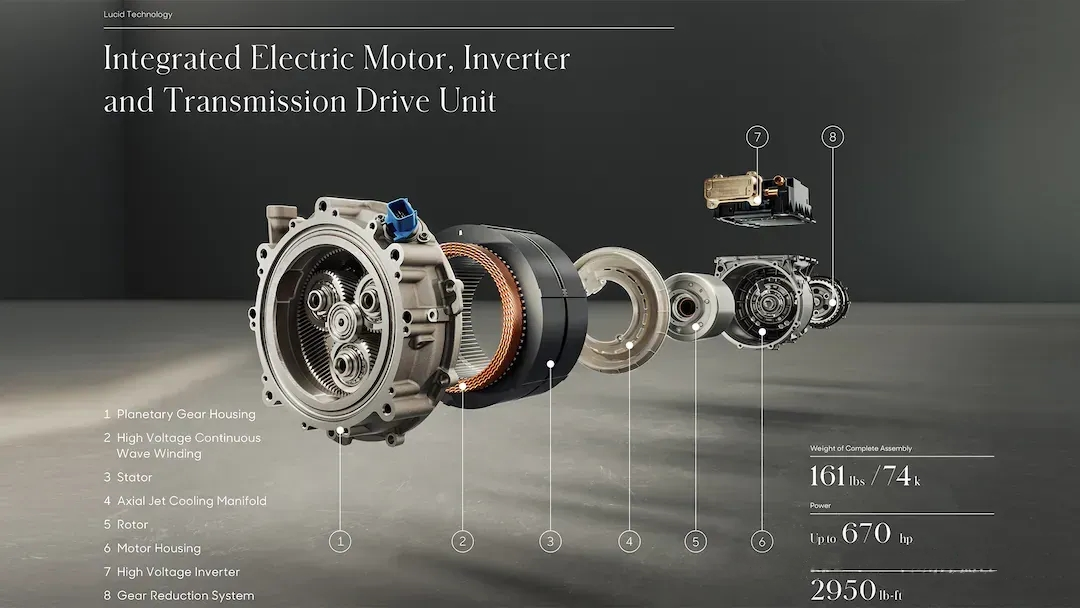

A liquid-cooled motor is a type of motor that employs a liquid cooling system to regulate its temperature. Compared with traditional air-cooled motors, liquid-cooled motors feature higher heat dissipation efficiency and can maintain stable operation under high-power and high-load conditions.

Liquid cooling systems typically utilize water cooling (including ethylene glycol solutions), oil cooling, or other coolants, with cooling methods such as cooling jackets, built-in cooling channels, and direct cooling of rotors or stators.

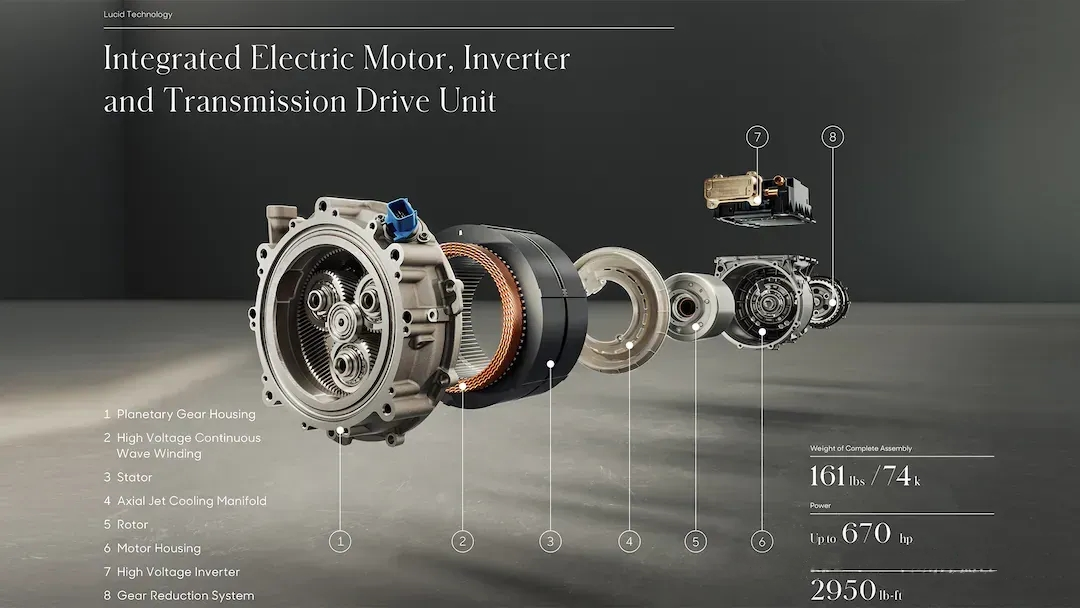

Engineers at Lucid Motors believe that narrow magnetic "dead zones" exist between windings, where slender cooling channels can be created without affecting magnetic flux. These channels allow cooling oil to extract more heat from areas closer to the heat source (within the copper). The oil flows out of these narrow channels through pinholes, which spray the oil onto the exposed copper windings.

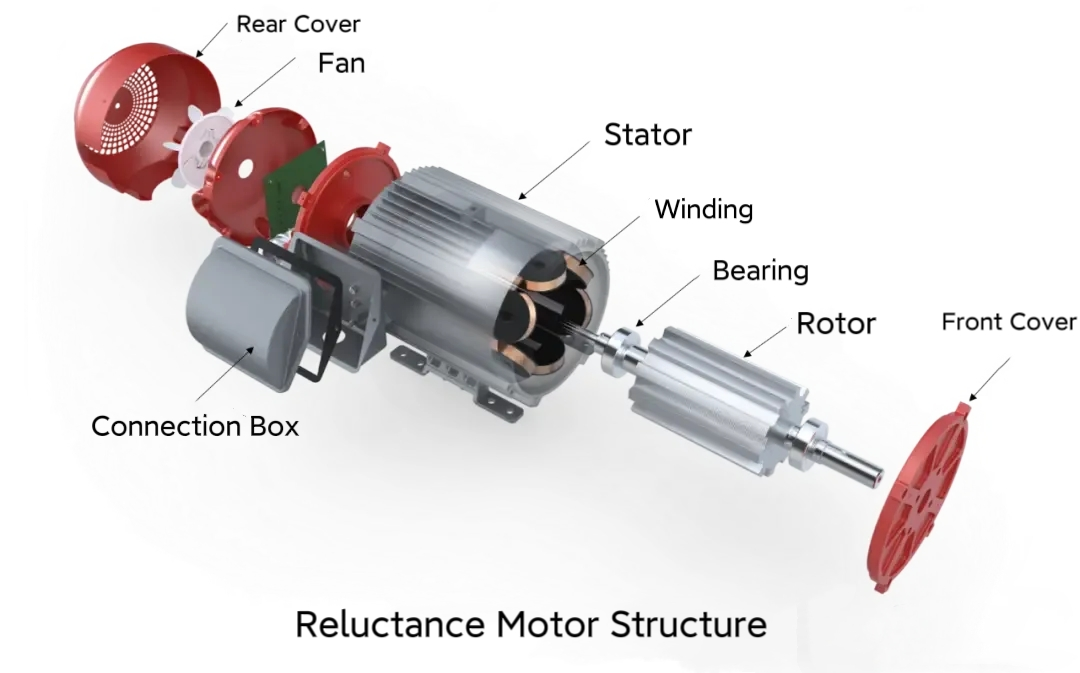

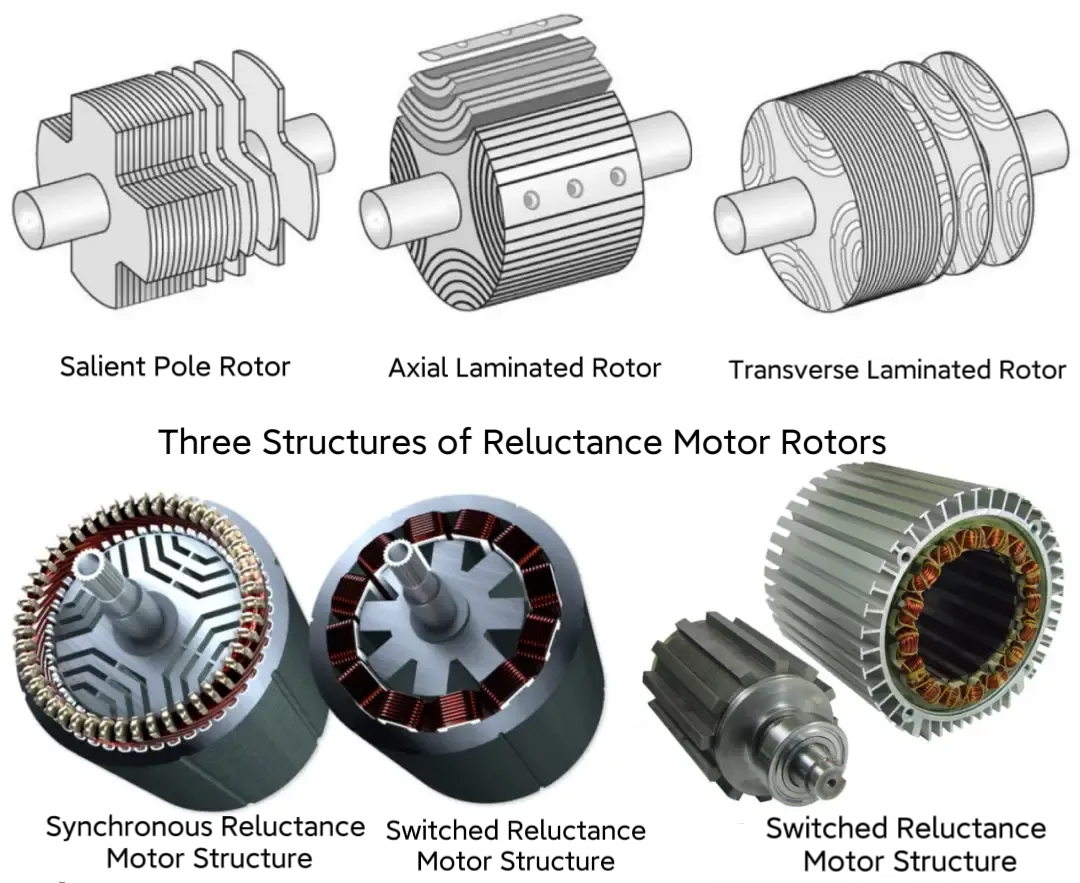

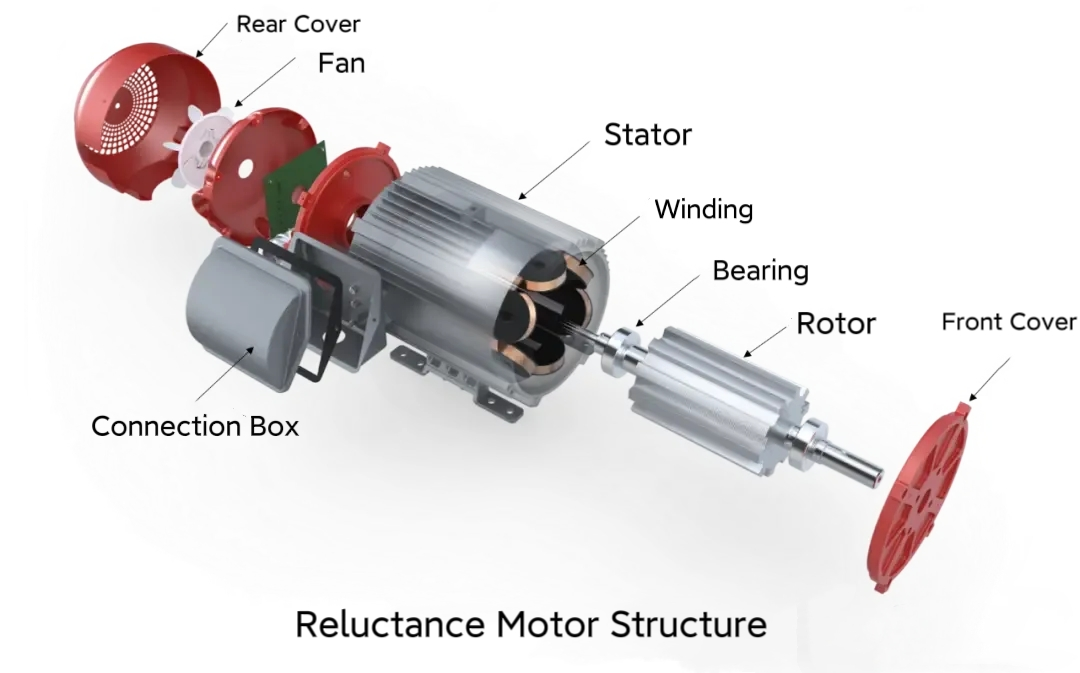

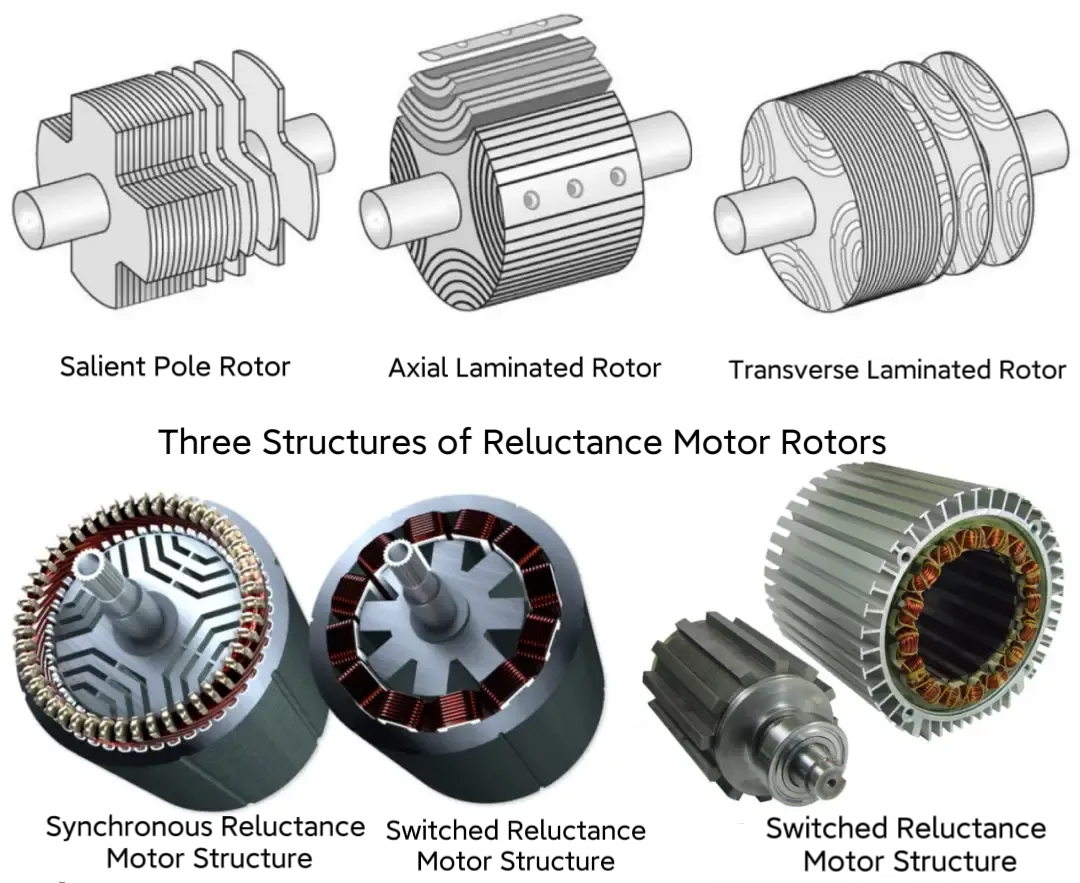

7. Reluctance Motor

A reluctance motor generates torque relying on magnetic reluctance characteristics. It has a simple structure, requires no permanent magnets, and is suitable for high-temperature environments. It is efficient, reliable, and low-cost, making it suitable for applications requiring high torque density and energy efficiency.

Reluctance motors are generally divided into two categories: Synchronous Reluctance Motors (SynRM) and Switched Reluctance Motors (SRM).

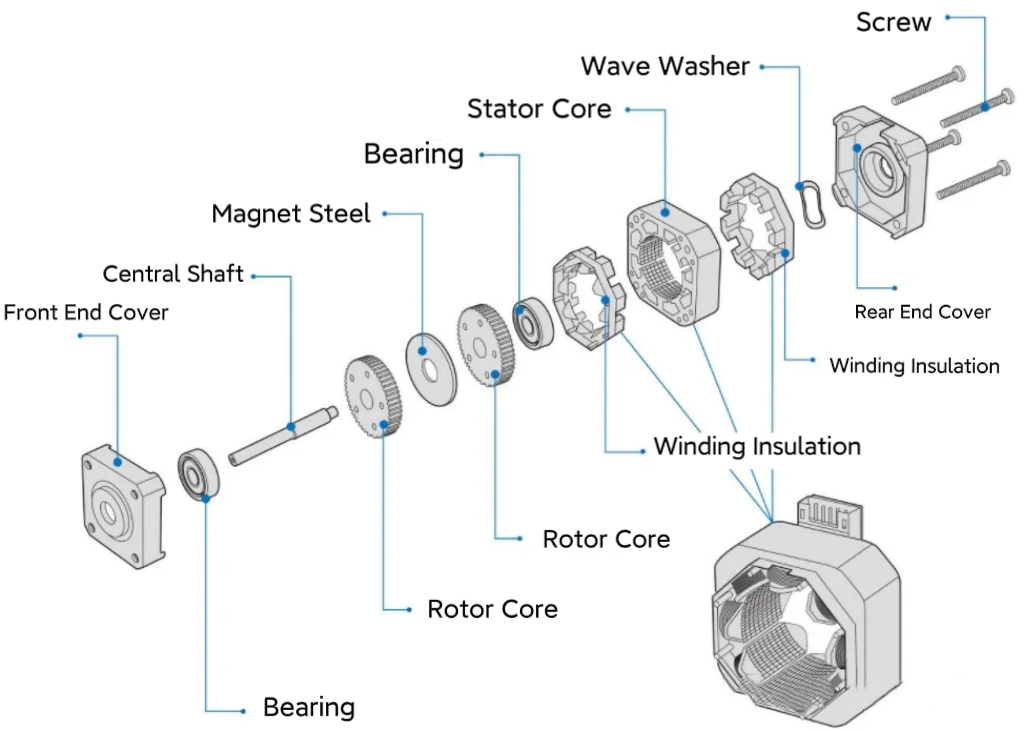

8. Stepper Motor

A stepper motor is a discrete-control motor where the rotor rotates a fixed angle (step angle) with each electrical pulse input, enabling precise position control.Key Features:

Precise positioning without a feedback system.

• High torque and stable low-speed operation

Suitable for applications requiring precise control.

• Simple structure and low cost

Widely used in industrial automation and consumer electronics.Common types of stepper motors include Permanent Magnet (PM) stepper motors, Variable Reluctance (VR) stepper motors, and Hybrid (HB) stepper motors.

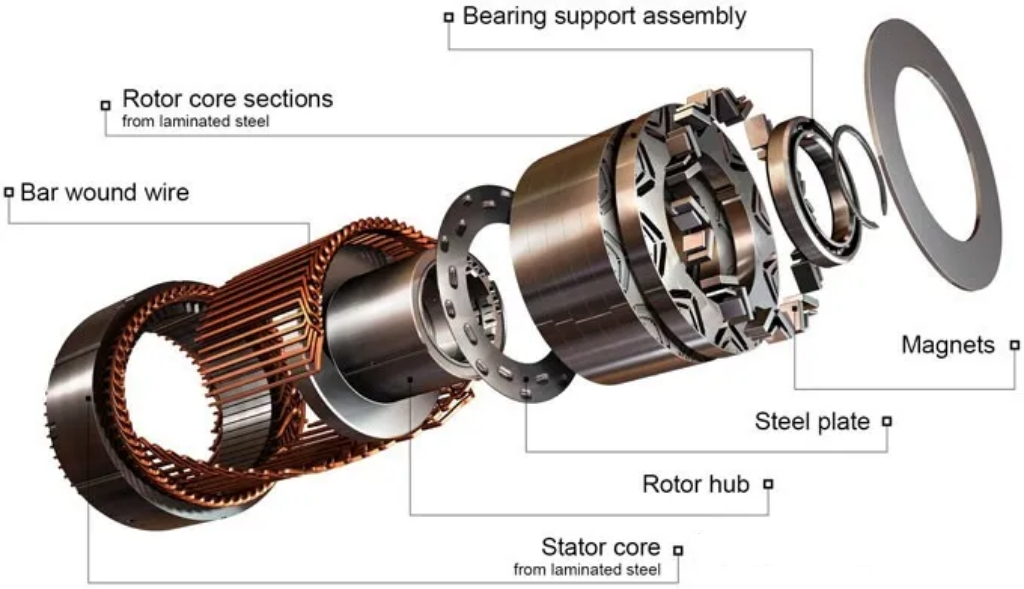

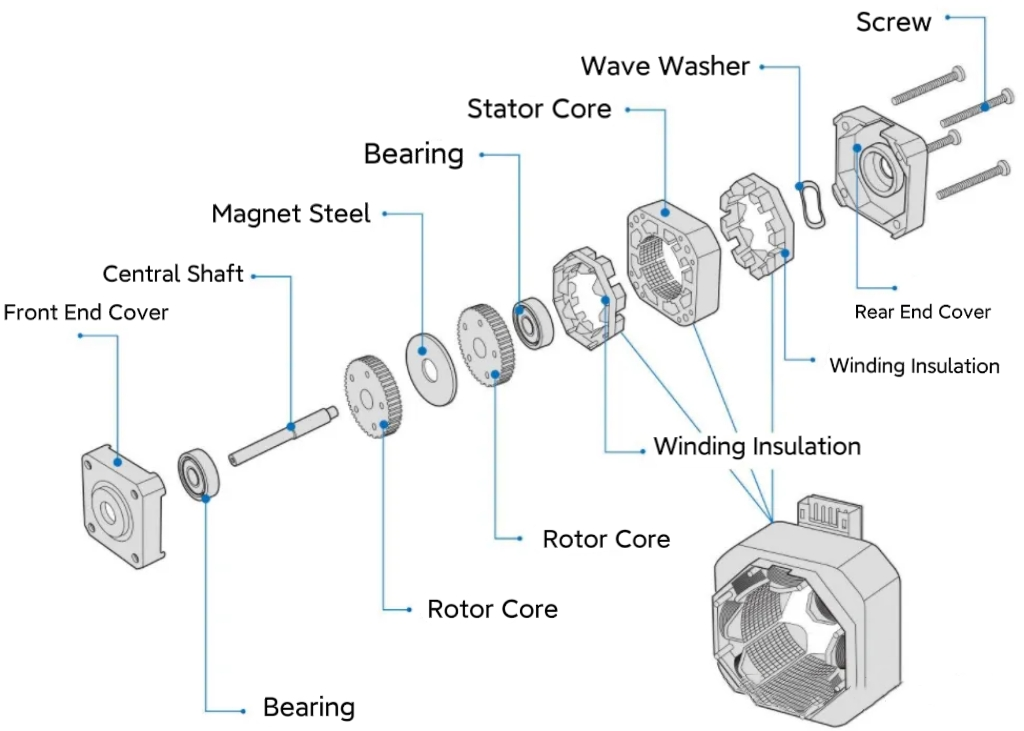

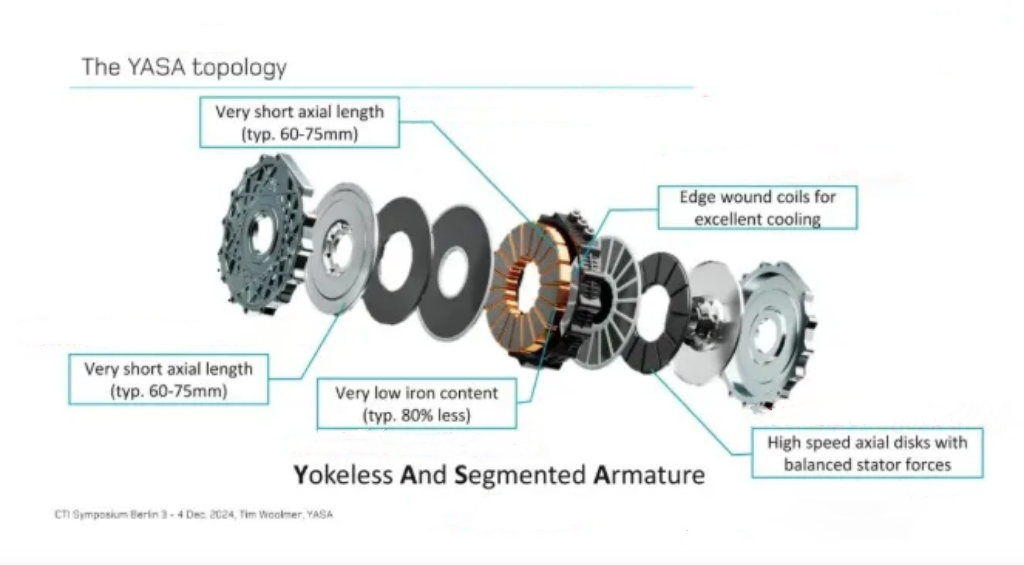

9. Axial Flux Motor

An axial flux motor is a special motor topology where the magnetic flux direction is parallel to the motor shaft, differing from traditional radial flux motors (where flux is perpendicular to the shaft).

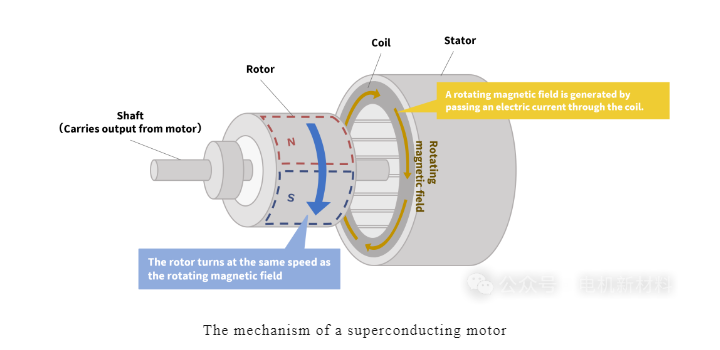

10. Superconducting Motor

A superconducting motor is a type of motor that uses superconducting materials as windings or rotor components. Compared with traditional motors, it features higher power density, greater efficiency, and lower losses.

Superconducting materials exhibit zero electrical resistance and perfect diamagnetism (Meissner effect) at low temperatures, enabling motors to significantly reduce copper losses and iron losses while improving energy conversion efficiency.

Superconducting motors can achieve both lightweight, compact size and high power simultaneously.

Hot News

Hot News